Harvest 2021

There was a slight element of apprehension for Harvest 2021 within the business as the challenges of Harvest 2020 remained firmly in our memories. Whilst it is widely accepted that the industry is never straightforward, the previous year was particularly arduous and Dyson Farming were pleased to welcome improved yields and quality across the crops as Harvest 21 progressed. The well documented escalating costs of fertiliser and fuel added an element of pressure for the next harvest. Dyson Farming remain committed to investing in their soils with a renewed focus on cover cropping, utilisation of organic manures and advancement in precision technology such as “green on brown” and focusing on the wider environment whilst maintaining output at a lesser cost.

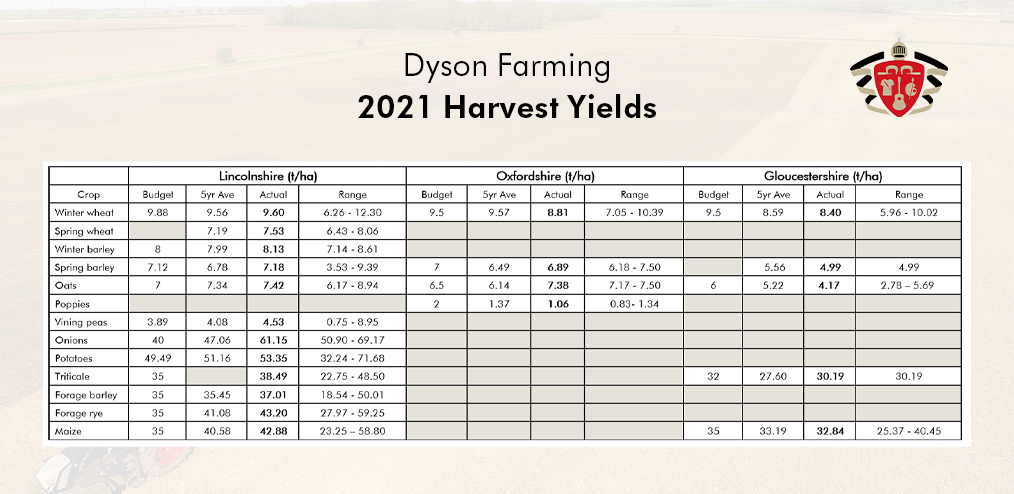

Cereal crops overall performed well with second wheat in some cases outperforming first. Reports of low bushel weights across several varieties were attributed to the frustration of a wet harvest without any rain. Increased volumes of ergot has been reported in some wheat samples; this was a consequence of the weather conditions and residual spores from previous cropping years however protein content across the board for milling wheat has been excellent. The largest area of winter wheat c.4,100ha is grown in Lincolnshire, the yields aligned with the 5-year average whilst Oxfordshire and Gloucestershire reported below their 5-year average.

Spring barley results across the business have been encouraging with the entire crop for 2021 presenting low grain nitrogen levels and excellent germination which bodes well for malting barley requirements.

Energy and forage crops performed ahead of budget across the business and despite the spell of hot weather experienced in the middle of July which meant that an area of rye was set aside for combining as the dry matters were too dry, the overall quality has been good for gas production in our AD plants.

Potato yield was slightly below budget on processed however the packing potatoes yielded exceptionally well. Overall, the crop has performed in line with expectations and presented a good quality.